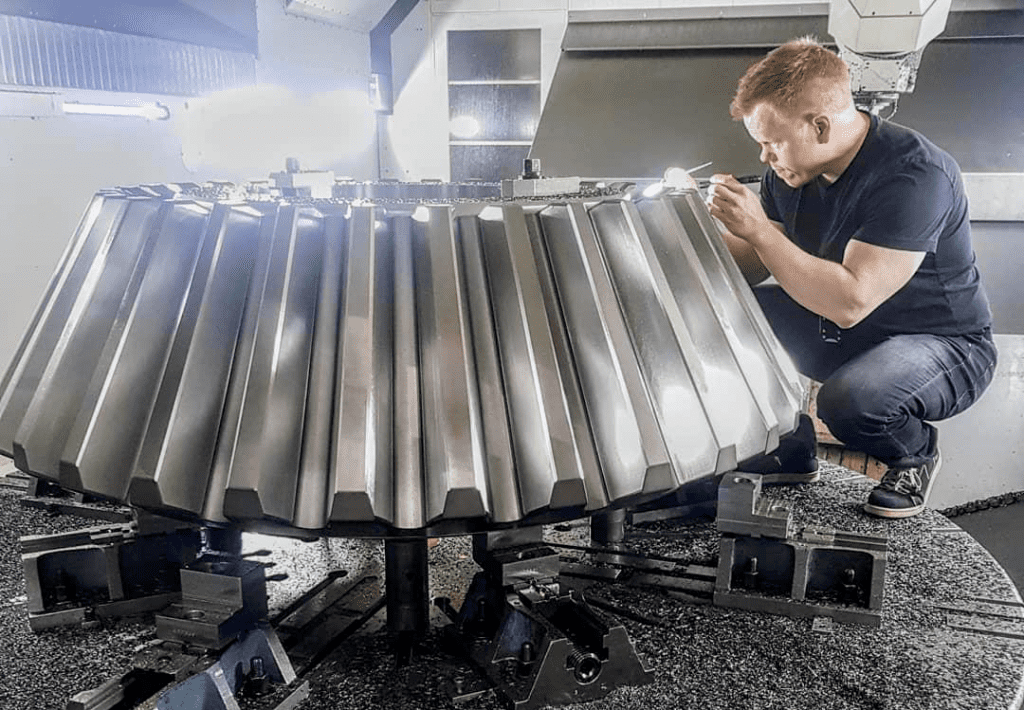

After using all sophisticated testing methods, we still count on human intuition.

The magnitude and measurements of projects particularly in the steel, mining and marine industries tend to make big headlines. These projects characteristically also impose the biggest demands on mechanical power transmission. State-of-the-art equipment, sophisticated testing and profound experience are all needed to the max.

It is lasting news?? that at ATA Gears we have the machinery to produce almost any size of gear wheels and pinions to serve those and any other industries. So far the biggest we have produced are in the 3-meter diameter range, weighing some 10,000 kg. And, most importantly, owing to the “practice” of over 80 years of bevel gear production, we can guarantee an accuracy of at least class Q=6 regardless of the size of the gear wheel.

We’re often asked how long it takes to produce such gigantic gear wheels. And we know that exactly. Once we receive the material, the production process takes just 11 weeks. And we rely constantly on our own heat treatment and material know-how. That ability to perform all the steps in the manufacturing process in house is very important, especially in the current circumstances. And when working on big bevel gears, we also trust the big material brands, such as Lucchini Mamé Forge, Brück, Dirostahl ja Hammerwerk Erft. Because we see it as our duty to manage as many of the risks as possible relating to big gear wheels for our customers.

What is your power transmission need? How big a bevel gear or other power transmission component do you need? Call the Gear Doctors or send your requirement to tami.komssi@atagears.fi. We look forward to meeting any challenge you may have.