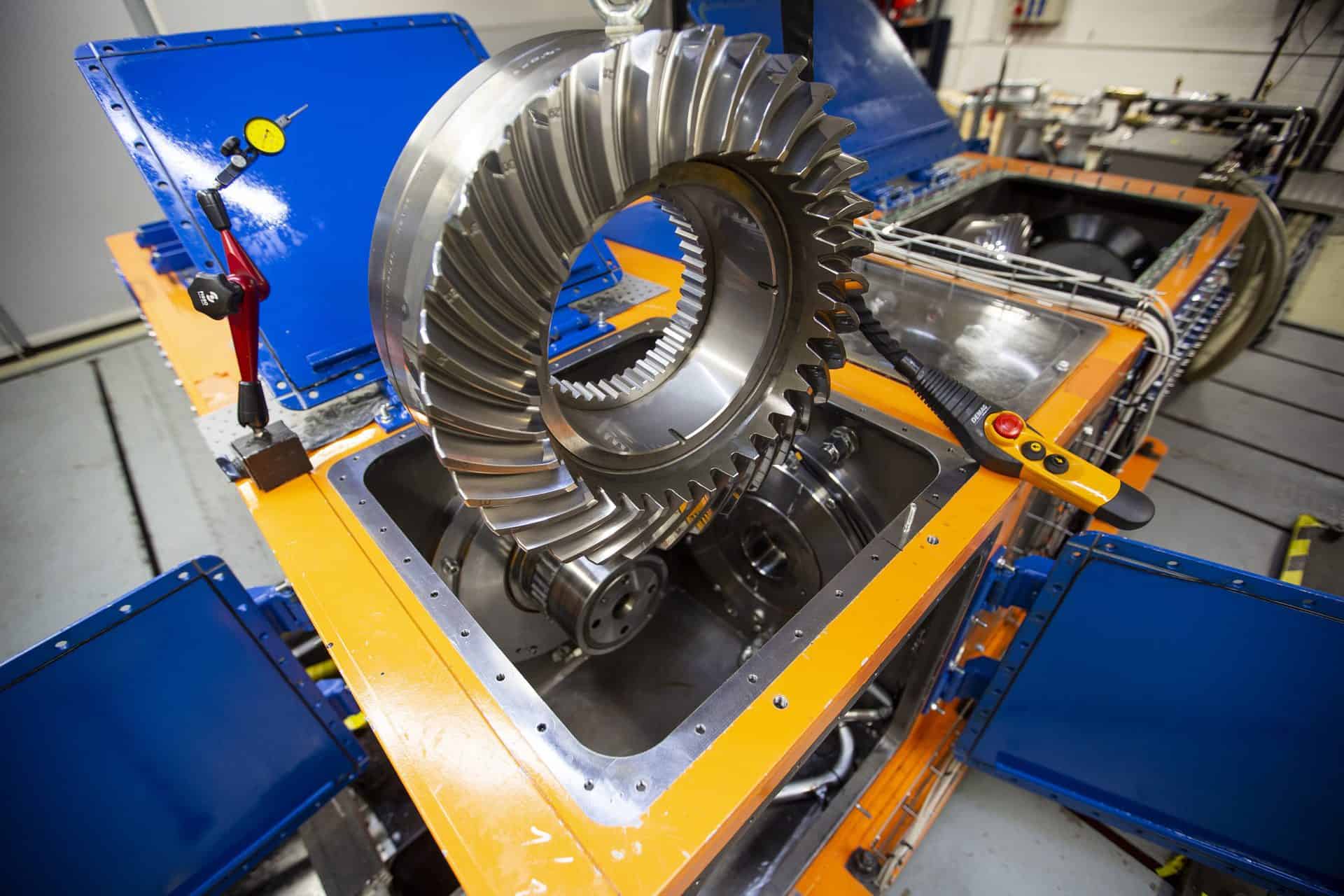

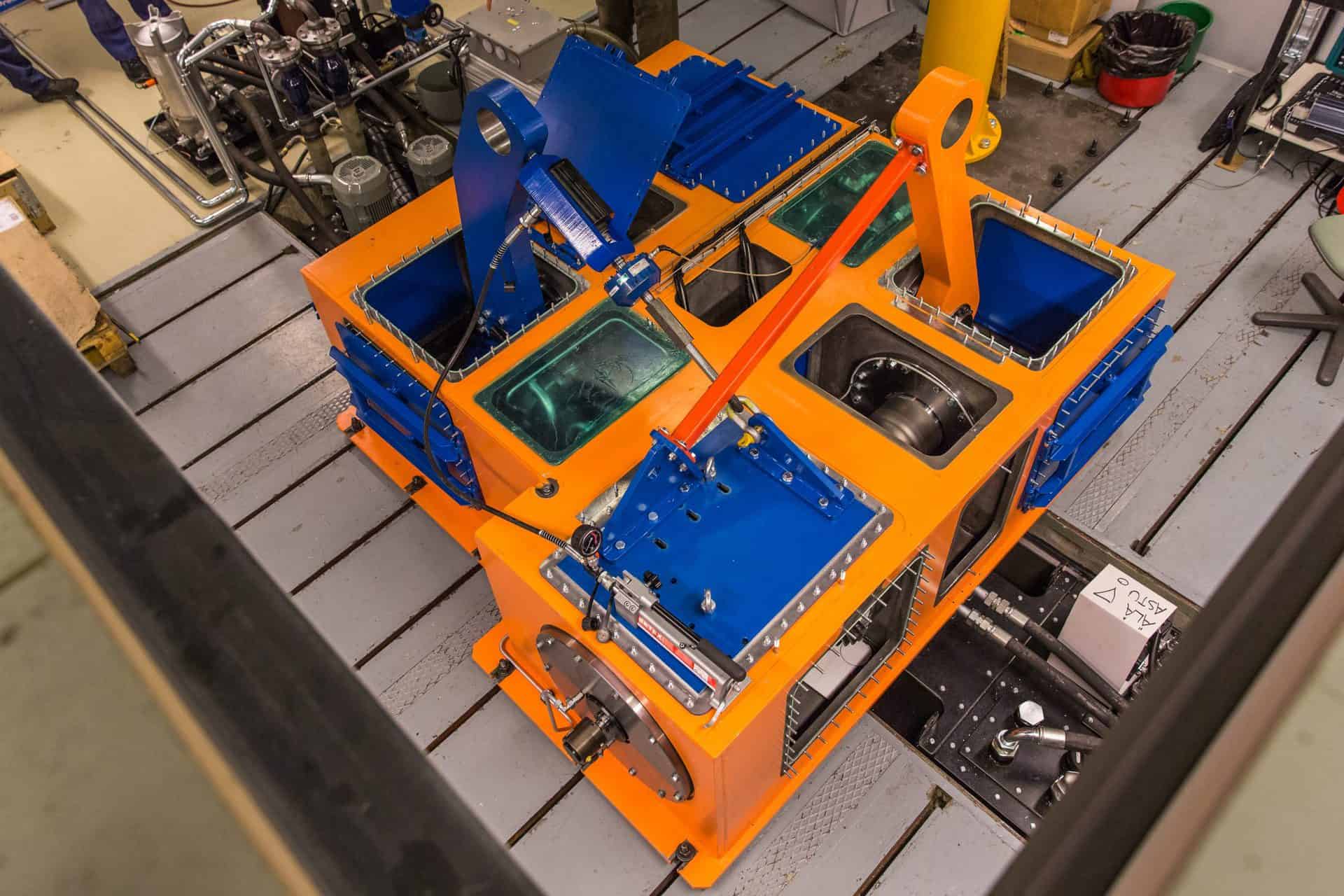

As the Gear Doctors of ATA, we are steadfast in using one facility to put innovation to a continuous test. A joint venture between ATA and Tampere University, the Test Bench involves testing the endurance of bevel gears in a special bevel gear endurance test rig. It is definitely a tough place for bevel gears. The loads used are twice higher than normal to make the bevel gears break in 2-3 weeks, when normally they would last for decades.

Loads of information

We collect information through the multiple sensors in the test bench. Torque is measured at four axles, vibration in two test corners in three different directions, and additional measurement targets including speed, temperature, oil flow and metal particles are also taken from the bevel gears. Several signals are received at intervals of mere milliseconds, and the test runs typically last for weeks – so what is essential needs to be filtered from a vast data flow.

The purpose of signal processing is to learn to recognize the symptoms, warning signs of various kinds of tooth damage. The measurement system recognizes malfunctions in machine running and orders shutdown before the actual test bench can break and also cause danger to the bevel gears being tested.

Breaking ground for future progress

It’s all because we insist on knowing, and being sure about it. The purpose of all this is to develop and verify calculation tools for gear tooth design, to find out and indicate to what extent tooth contact optimization and various product options relating to tooth finishing really improve bevel gear endurance. This should be highly beneficial for any demanding application.

ATA Gear Doctors use these calculations to model bevel gear endurance. The goal is to produce concrete test results for our customers and classification societies to demonstrate the superiority of optimized bevel gears. This allows ATA to recommend and enables its customers to choose new product options, such as super-finishing treatment when there is solid proof that they prolong bevel gear life.

With Test Bench, ATA also complies with the global trend for larger machines and the consequent interest in the effects of scale. Testing larger gears is a reality.

Significantly reducing test times while obtaining new and reliable data paves the way for future progress – both in ATA Gears’ own product development and increasingly as part of our customer service.

Gábor Szánti, ATA’s Product and Process Development Manager

EMAIL