There are two SEW-EURODRIVE companies in Finland, SEW Industrial Gears in Karkkila and SEW-EURODRIVE in Hollola. Both are ATA Gears’ customers: The Karkkila unit has many of its bevel gear pairs manufactured by ATA Gears for use in the new gear units it itself manufactures, while the Hollola unit sources parts and components for the gears they service – especially big planetary gears. A good cooperation routine has been established between the three companies.

Two companies with special knowhow

Avoiding unplanned production stoppages results directly in increased availability and offers a strong competitive advantage for the process industries. As a pioneer in drive technology, SEW-EURODRIVE is also a frontrunner in making that vision a reality. The group’s service centre in Finland, SEW-EURODRIVE Hollola, near the famous winter sports city of Lahti, offers a comprehensive range of field services including visual inspection, vibration measurement, condition monitoring as well as assembling and disassembling gear units onsite.

SEW-EURODRIVE Hollola services industrial gears of all sizes in their area of responsibility – from two-fist-sized units to units weighing tens of tons. Although the trend is clearly towards proactive service projects, they never refuse a repair. SEW-EURODRIVE has special knowhow and resources in vibration measurement, and in interpreting the data they provide – determining on which part the cause of a problem resides.

There are less companies which really master the production of extra-large gears – the different structures, materials and techniques.

SEW-EURODRIVE manufactures planetary gear units, for example in Brazil and China, but in demanding service projects, because of obvious logistics reasons, they often prefer to turn to the Finnish ATA Gears for help, especially with extra large gears. “There is abundant knowhow in the world for power transmission components made of carbon steel but there are less companies which really master the production of extra-large gears – the different structures, materials and techniques, and also understanding the dimensioning aspect in the equipment of which these gears form part. ATA Gears is such a company,” Plant Manager Kari Pohjonen of SEW-EURODRIVE Hollola lists their reasons for relying on ATA Gears as a key supplier.

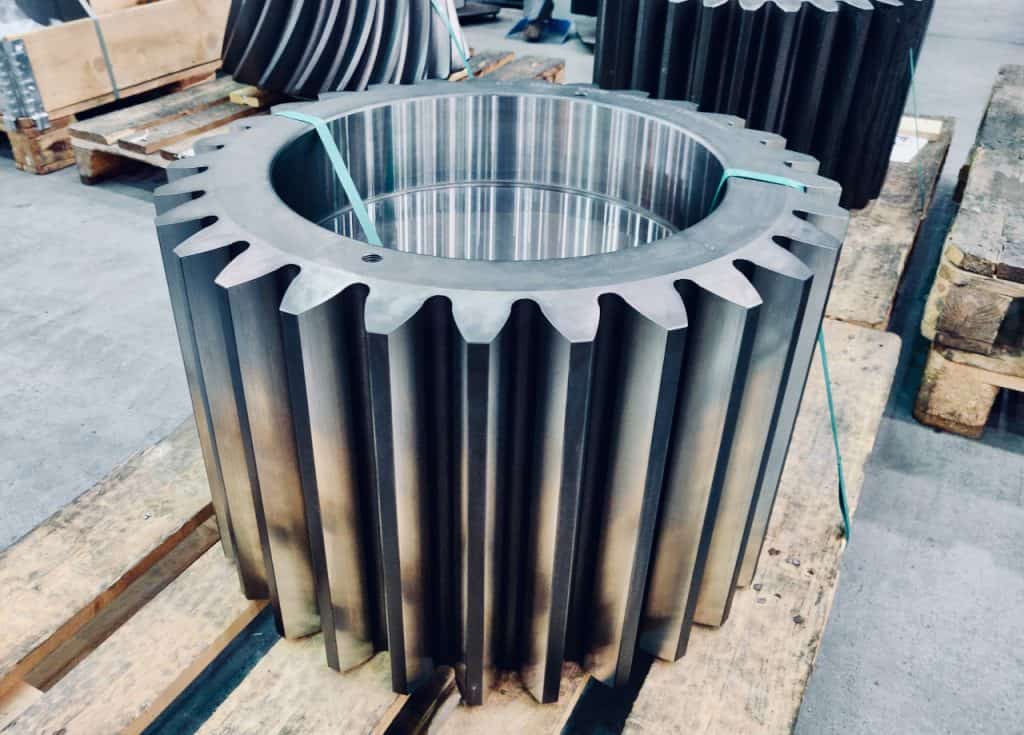

Delivery of a truck-size planetary gear set

In a case at the bigger end of the scale, an extraordinarily big planetary gear unit was needed for a mill drive in Northern Europe. This customer needed all vital elements of the planetary gear – the ring gear, planetary gears as well as the sun gear. Drive units of this size are rare in the Nordic countries – amounting to the weight of a big truck or 40 tons. This really big planetary gear set was delivered by ATA Gears to SEW-EURODRIVE Hollola and then to their customer in 2020. ”The gear set was characterized by a really big gear ratio with a 0.5 m sun gear in the middle and around it planetary gears and also ring gear with an internal tooth pattern functioning as the frame for the entire structure,” explains ATA Gears’ Sales Manager Jukka Helldan, who has been been SEW-EURODRIVE’s contact at ATA Gears since 2002. “Because SEW-EURODRIVE is one of the world’s biggest manufacturers of industrial gears and possibly the best, we are obviously proud of this project and their trust in us,” Jukka Helldan goes on.

Cooperation between SEW-EURODRIVE Hollola and ATA Gears to accomplish this project started already a few years ago when Kari Pohjonen met with ATA Gears’ Sales Manager Tami Komssi at the Subcontracting Fair in Tampere and both immediately saw great opportunities to serve the end customers with big gear units even better than before. As a result, ATA Gears has delivered several planetary gears and other extra-big components to SEW-EURODRIVE.

Kari Pohjonen underlines the indispensable importance of knowhow: The supplier of gears must know what they’re doing, how to manufacture the parts, the technologies and the metallurgy. At its best, it is seamless cooperation between the experts of the two companies, the experts at SEW-EURODRIVE and ATA’s Gear Doctors. In the absence of their own design resources, SEW-EURODRIVE’s Hollola unit in particular relies on ATA’s help – and so does the gear manufacturing unit of SEW Industrial Gears Oy in Karkkila.

We need the best quality and a reliable supplier.

SEW-EURODRIVE always want to take things further: They constantly invest in additional resources, and can make the decisions fast – a virtue of an agile family-owned company. The latest trend is towards manufacturing really big axles, even with over 1.5-meter diameter, long grooves, tube axles and also with internal tooth pattern. To support that trend, ATA Gears has been delivering ring gears and cylindrical pinions to SEW-EURODRIVE’s service unit in Hollola. Because the SEW Industrial Gears manufacturing unit in Karkkila is in many cases responsible for the design stage in Hollola’s service projects, good routine cooperation has been established among the three companies.

The strong partnership between ATA Gears and SEW Industrial Gears has long roots

ATA Gears has been a trusted supplier for the SEW-EURODRIVE companies in Finland – even longer for the manufacturing unit in Karkkila than for the Hollola service unit. The purpose of SEW Industrial Gears Oy is to act as the appointed supplier of gear units for the SEW-EURODRIVE companies. Every year, ATA Gears is involved by supplying almost 1,000 pairs of small bevel gears to SEW Industrial Gears Oy. Measured in terms of gear pairs volume, SEW Industrial Gears Oy in Karkkila is ATA Gears’ biggest customer.

Purchasing Manager Petri Haikonen has been working for SEW Industrial Gears for two years, and before that for other power transmission specialists for several years, so he not only knows gears and drives through and through, but has considerable experience of working with ATA Gears. He sees ATA Gears’ role as strategically important: “Although in most of the drive units we manufacture the structure is mainly composed of cylindrical gears, there is almost always one bevel gear pair included, and for that we need the best quality and a reliable supplier. And we – and I – have been working together with ATA Gears for several years, so we are confident they have the knowhow and we know what we get.”

Special gear units is clearly one of SEW Industrial Gears’ growth areas in the future. “For those in particular we need an agile partner. We really hope ATA Gears can continue to accommodate, because they need us and we need them,” says Petri Haikonen.

We – and I – have been working together with ATA Gears for several years, so we are confident they have the knowhow and we know what we get.