We all prefer doing meaningful and cost-effective work, right? And what could me more meaningful than making sure that the precious resources available are effectively used to their full potential. That’s what ATA’s ReVive™ service concept is all about.

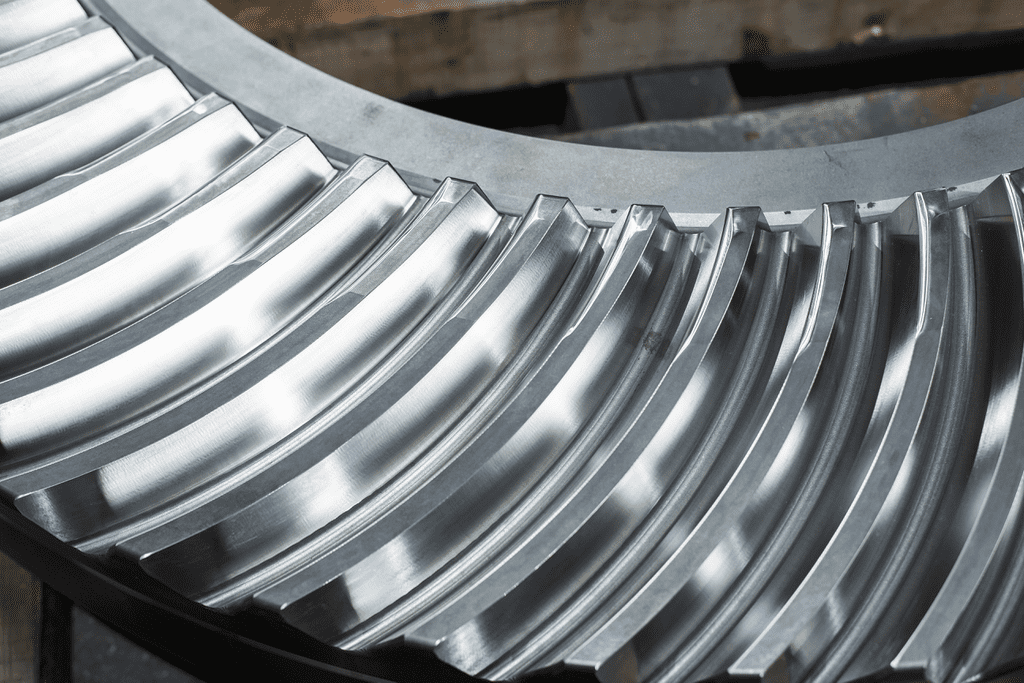

In some cases, the harsh environments where bevel gears are operating can leave their marks on the gears, denting and other signs of excessive stress and wear. But help is at hand: ATA’s ReVive™ service concept comes to rescue.

Mild damage or wear marks observed on the gears may not be immediately detrimental to the working of the gears, but may progress and lead to a failure at a later time.

The normal action in such a situation is to replace the gears. But this means producing new gears, which is, of course, a major investment in resources and time. Our experience shows, however, that in many cases it is entirely feasible to restore the power transmission capability of the existing gears. Such processes are actually already widely applied in many other branches of mechanical power transmission industry, for example in bearings, optimizing assets and improving sustainability.

As an advanced remanufacturing and reengineering service, ATA ReVive™ offers an efficient alternative to a new component. The service always starts with a thorough inspection of the components and an analysis of the application environment to find the root cause of a problem. Based on this, the most appropriate remanufacturing plan is prepared.

The actual process may include various kinds of working steps, ranging from simple rust removal to cavitation damage repair, and sometimes complete remachining of the tooth flanks. ATA’s ISF-treatment (IsoTropic Superfinishing) can also be applied, for example to eliminate scuffing or micro-pitting problems.

It is important to note that ATA ReVive™ is not restricted to damaged gears. It can equally well be applied to immaculate gears – used or unused – that are just destined for hard work in an environment other than specified in the original design criteria; for example different load, lubrication, rotation direction etc.Using the information of the application and applying ATA’s advanced system-level optimization tools, ATA’s engineering specialists can define an updated gear specification that improves gear performance and reliability in the intended application.

So ATA ReVive™ has several meanings: restore, reuse and repurpose.

And the benefits are remarkable: longer service life, less downtime and savings on costs.

And maybe most importantly: less environmental impact.