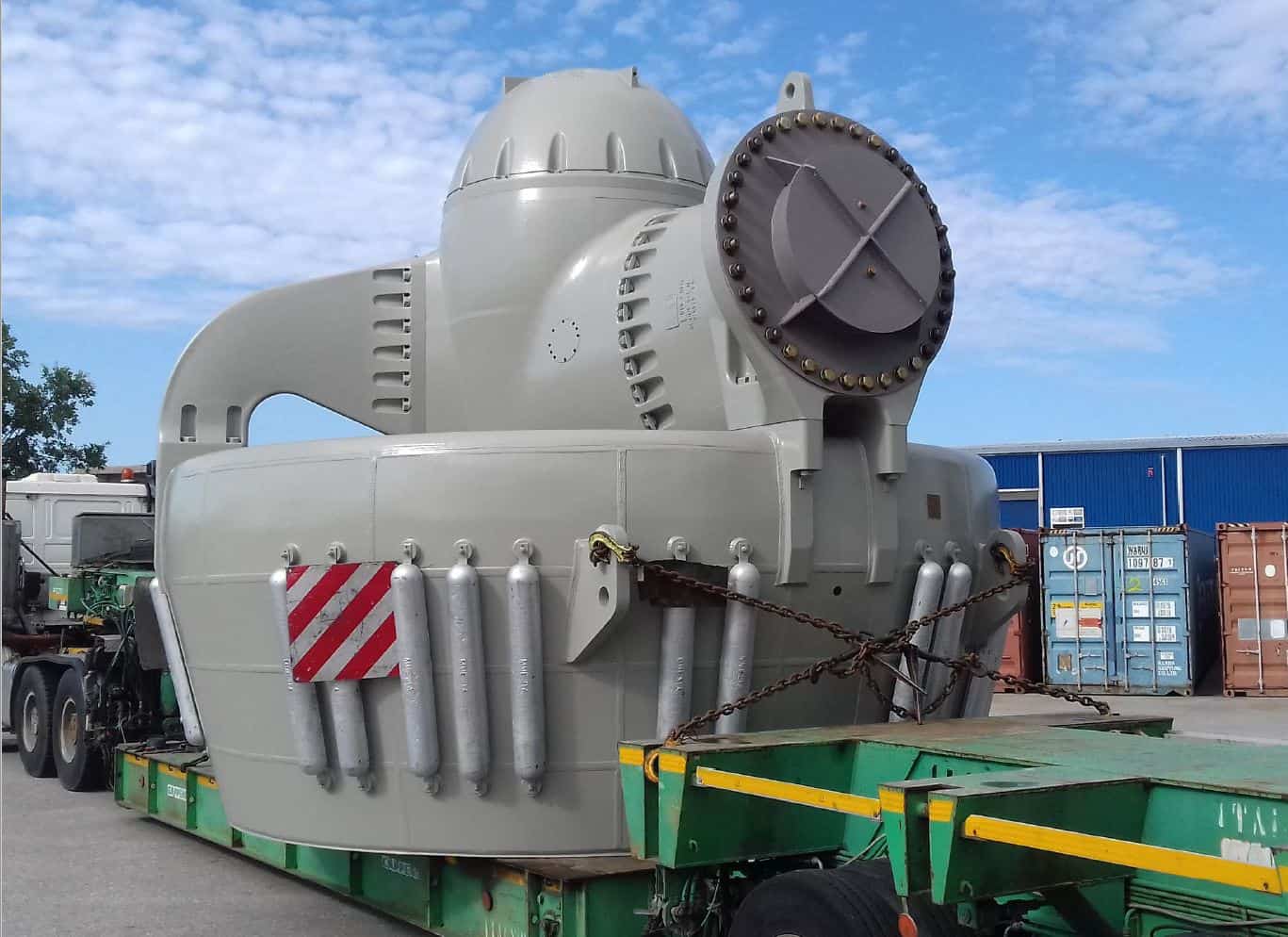

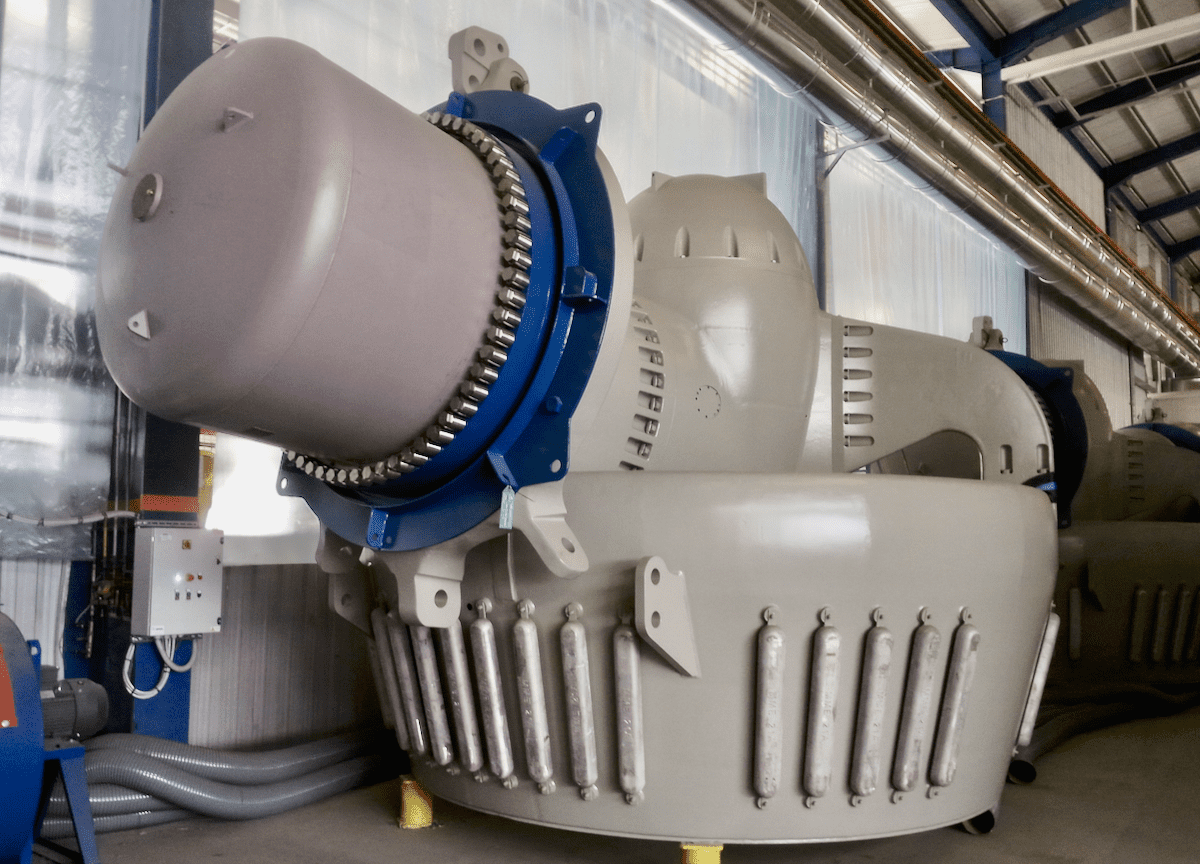

For the Orion, reliability is everything, and everything is at the biggest end of the scale. To give an idea of the size of the mega-calibre equipment involved, the main propulsion system has a capacity of 5,000kW per unit, the diameter of the propellers is between 3.2 and 3.9 m, and the bevel gears are between 1.2 and 1.6 m in diameter. Wärsilä’s Lauri Tiainen describes the scale of the Orion operation: “Since the ship carries both the normal ship’s crew and the builders of the wind energy park, it includes a floating hotel capable of accommodating more than 200 persons.”

In maritime applications, LNG-fuelled and dual-fuel systems are the fastest growing solutions. The reasons are easy to understand: These systems are both competitively priced and meet the ever stricter environmental requirements on the seven seas. Technology group Wärtsilä has supplied the engines and other propulsion machinery for the world’s first and biggest offshore construction vessel Orion, owned by the Belgian operator DEME, and specially designed for wind farm installation. ATA Gears is the chosen partner to help with the design and production of the massive bevel gears used in the thruster systems.

With an unusually large load-carrying capacity and lifting height, the Orion has 8 thruster systems, all of them equipped with bevel gears by ATA. Both Wärtsilä and ATA have contributed to the newbuild project right from the conceptual design stage. The thruster system includes several innovative features. ”For a ship sailing under the highest DP3 class notation and needing to operate in a range of different scenarios – for example even after losing an engine or thruster – we were determined to create a whole new solution, not stopping at mere sufficient safety,” says Vincent Klous, Manager Product Development of Platform Thrusters at Wärtsilä. He explains the innovative concept further: “Compared to a traditional 90-degree right-angled bevel gear structure, the propeller shaft of the thrusters is tilted 8 degrees downwards and the actual shaft angle is 98 degrees.”

This offers several operational advantages and sustainable benefits, such as up to 20% higher efficiency during dynamic positioning compared to traditional thrusters, and that translates into 20% less power needed. It also provides longer life and greater reliability of the equipment. Under the new environmental legislation, oil leakage must be limited in all possible ways, so Wärtsilä’s team have decisively taken the green approach. All oil consumption of the thrusters in the different sealing arrangements is monitored and fed back to the ship to prevent oil spillage to the environment.

The quality and performance of the gears and the thruster system have been meticulously tested by Wärtsilä and ATA during the design phase. Lauri Tiainen, Director, Thrusters & Propulsion Control Systems at Wärtsilä, explains the importance of this: “In a ship which is the only one of its kind in the world, having the highest possible quality in all key components, combined with a high level of redundancy, is of paramount importance. Unlike a normal container ship, for example, it would be very difficult to find a stand-in for the Orion.”

To ensure consistency and high quality in its products, Wärtsilä works closely with qualified suppliers such as ATA Gears. “Within Wärtsilä, we have firm faith in quality components supplied by long-term partners,” states Lauri Tiainen, and Vincent Klous backs him up saying: “I have been working with ATA’s Gear Doctors now for 8 years and the cooperation is very solid and much appreciated in our company. The best results are always achieved through open and honest communication, and that we have succeeded in sustaining.”

Janne Koukkula, ATA’s Sales Manager, shares this opinion: “ATA’s mechanical power transmission experts participate in the design process, which is both comprehensive and profound. This is exactly the kind of cooperation we want to be involved in, since it is rewarding to both parties and delivers the best results.”