AN INTERGENERATIONAL LONG-TERM INVESTMENT

That’s what the customers of KOCKS, manufacturers of SBQ steel bars, like to call the German company. Something to be proud of, for sure. The SBQ (special bar quality) bars are slightly more specialized, as the name indicates. The specification is that when the end use, method of fabrication or subsequent processing requires unique characteristics, SBQ is the quality of bar to choose.

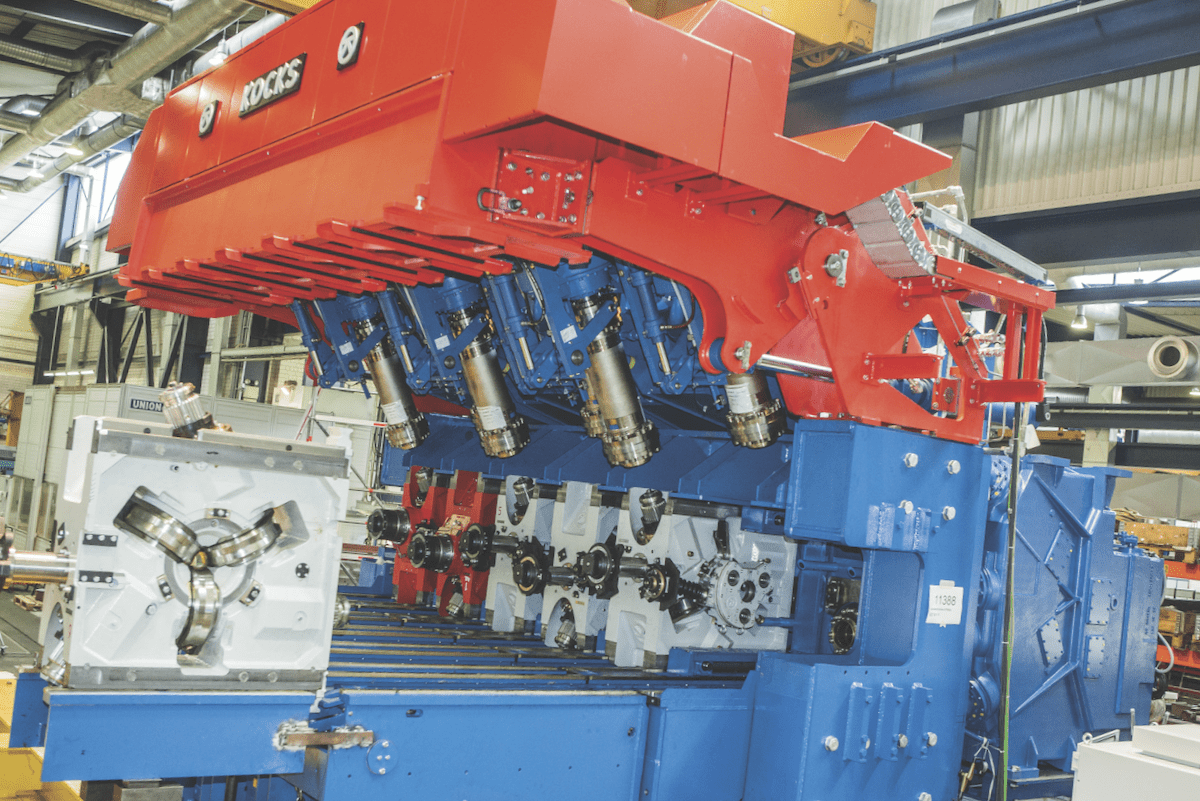

And the company is really special, too, KOCKS GmbH. Friedrich Kocks is the leading manufacturer of tube, wire rod and bar rolling mills in the industry. The company’s vision proclaims “Know how for tomorrow”, or more specifically, “vision to go with great ideas far beyond the existing in order to create a more reliable and a more honest world of steel of tomorrow”. And the company can claim uncontested credit for several innovations in the steel industry: The idea of applying 3-roll technology to forming tubes, as well as to wire rods and bars. Sizing technology. Reducing & Sizing Block enabling tolerances to be considerably tighter, both in terms of diameter and ovality. The free-size concept. The KOCKS SCS® (Size Control System). These are all KOCKS innovations.

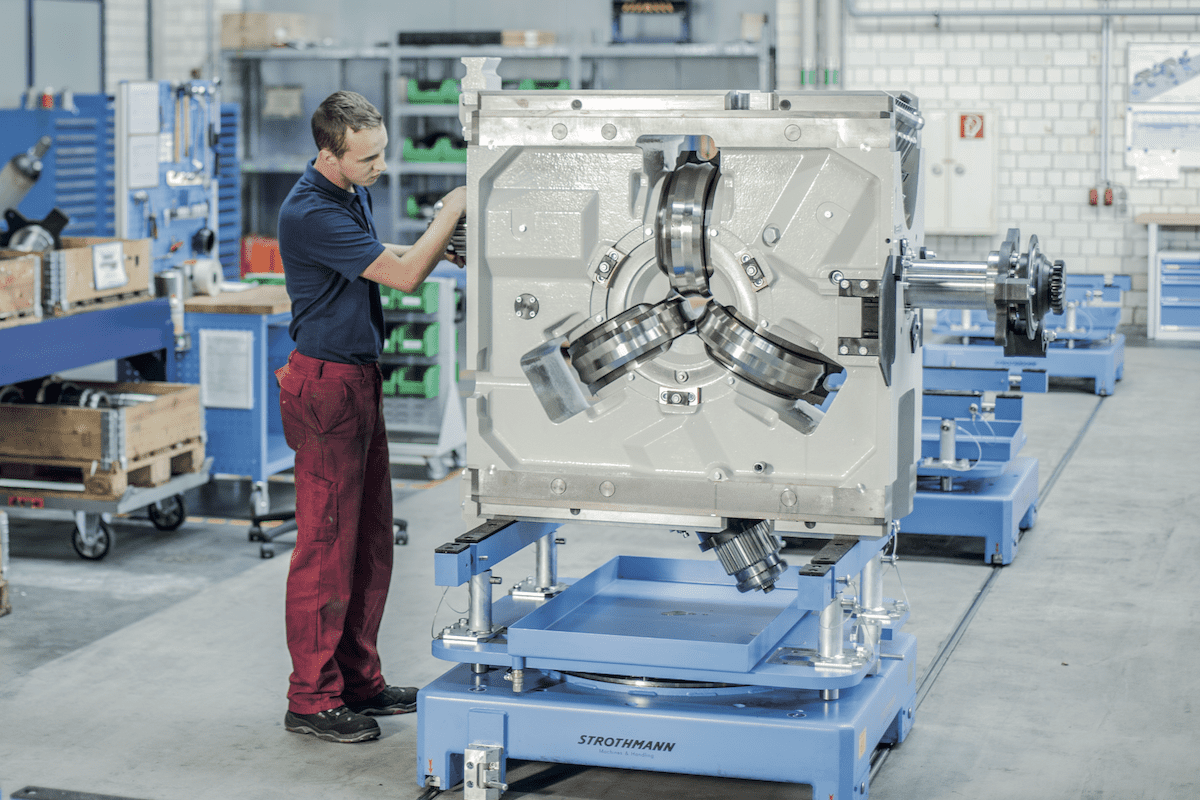

Built on expertise from more than 50 years of production experience boosted by modern digitized industry 4.0 production standards, the core components of the famous KOCKS block are manufactured in the company’s workshop in Bremen, Germany. The KOCKS rolling process is what determines the quality of the end product. “At the heart of the rolling mills, with a KOCKS 3-roll block, our customers make their product GOLD!,” another big statement by KOCKS.

A reliable partnership with ATA

“We first met ATA in 2000, but our relationship became closer in 2014, when we worked together with ATA on new technical developments,” Andreas Voss, General Manager/Purchasing explains their working relationship. “We order various sets of bevel gears that have been specialized for KOCKS. The bevel gears are used for the drive train of our KOCKS Rolling Mills.”

“In ATA we found a reliable business partner with a high level of technical knowledge and a great manufacturing performance in bevel gears. As we deliver high-quality products, it is important to have a supplier that is reliable and trustworthy,” says Mr Voss about KOCKS’s continuing relationship with ATA.

Using the latest R&D methods

ATA Gears have identified in KOCKS a demanding customer with very precise requirements in terms of product quality and dedicated to making their products meet their customer’s requirements right down to the last detail. ATA shares KOCKS’s commitment to customer satisfaction and product quality in all they do. As ATA Gears sales management puts it:

“As a producer of rolling mill equipment, KOCKS is known for high quality and precision in pipes and bars. It was essential for ATA to gain a profound understanding of the conditions and requirements for the mill gearboxes to work optimally so as to be able to provide optimally efficient parts.”

The test bench and other state-of-the-art R&D tools enable ATA’s Gear Doctors to analyse the behaviour of the gearboxes and make the necessary corrections to the bevel gears to be sure of optimal operating properties and long life. With ATA’s tailor-made gears, KOCKS can confidently continue to satisfy their customers.